Toho Photo Mask Spin Cleaners are utilized in Display Fabs around the world because of their reputation for outstanding performance and cleaning results. The need to achieve high cleaning efficiency for Photo Masks of all sizes means that customer needs drive the design and function of our products. Toho Technology Wet Process Solutions offer outstanding value with additional benefits that make Toho the clear best choice for long term intensive performance. Toho is an approved vendor for all leading manufacturers which demand Photo Mask spin cleaning to ensure outstanding cleaning results for the photo-alignment process.

Photo Mask Cleaning

Cutting Edge Wet Process Methodologies

Toho’s worldwide experience boasts a wide installed base of Photo Mask Spin Cleaners for various applications. This allows Plant Managers and Process Engineers alike to benefit from “best in class practices” and cutting edge Wet Process methodologies. The common features and configurations below are enhanced and customized to meet budget and application needs while taking advantage of second to none quality manufacturing and “kaizen” production methods developed in Japan for the Asian Flat Panel Display industry.

Common Modular Process Configuration

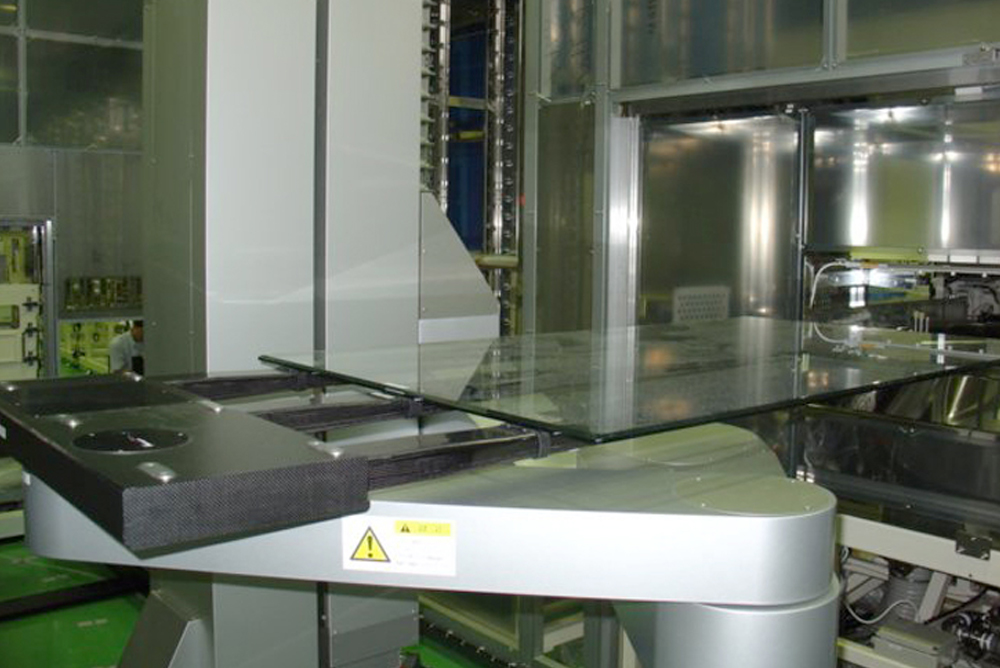

1. Robot Load / Un-load

2. Stable 4 Corner Leveling Sensors

3. Double Sided Cleaning

4. Alkaline/acidic cleaning or Chemical Free Cleaning

5. Brush Cleaning (Surfactant Application)

6. High Pressure Rinse

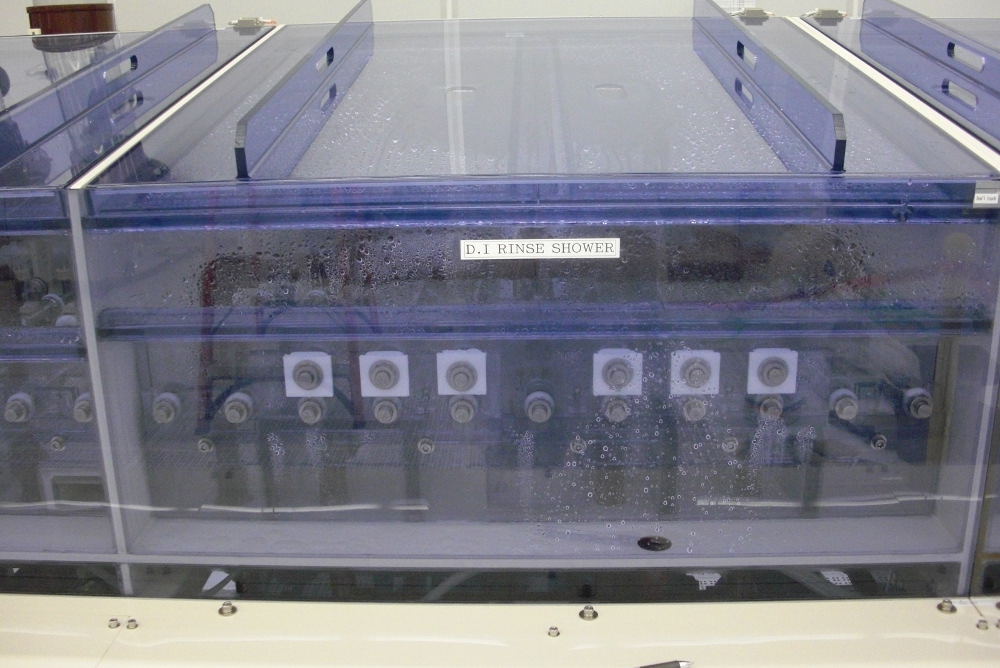

7. Final DIW Rinse

8. Air Knife high pressure CDA or N2

9. Un-Load

Optional Process Configuration

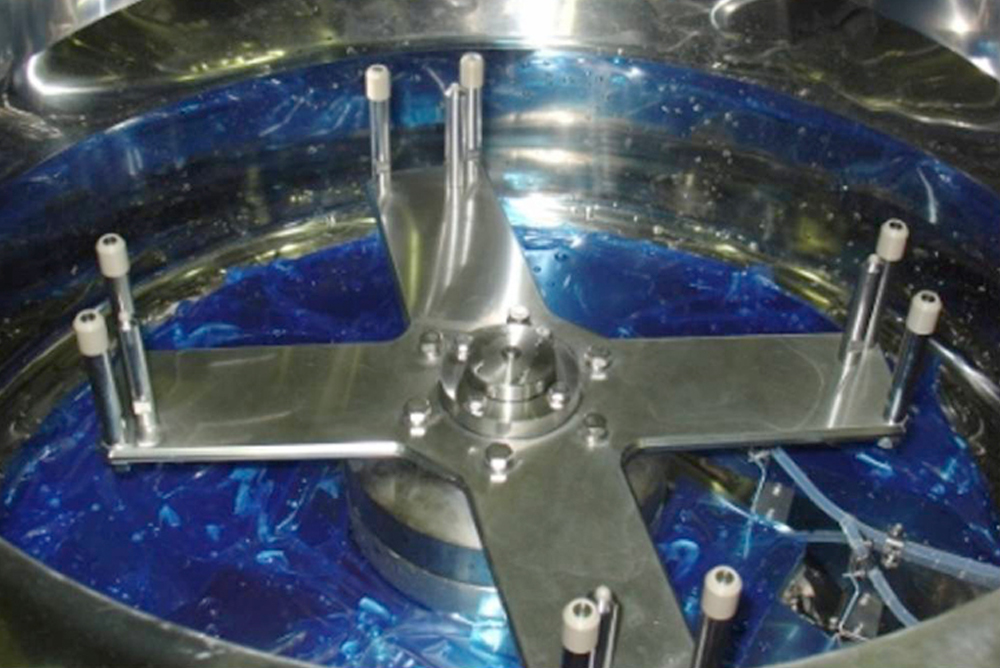

• Spin Wash, Rinse, Dry

• Gantry type Glass handling Mechanism

• HEPA filtration

• Bacteria Prevention systems to stop water born contaminants

• Ionizers in critical ESD control areas – Unload module

• Safety light curtains at openings

• CIM / Host PC interface

Toho Quality Build

• Designed to Ensure Mask Integrity and Damage prevention

• Easy access Maintenance openings

• Fully enclosed Process Chambers

• Built in exhaust

• Multiple safety interlocks, leak sensors, exhaust sensors, over-heat, dry pump and other built in safety systems

• Effective particle filtering system

Customized for Different Applications

Always an ever changing dynamic market place, the need to achieve high cleaning efficiency on Photo Masks of all sizes means that customer needs must drive the design and function of our products. Unlike other Wet Process equipment vendors, Toho does not offer a “one size fits all” line up. We realize that while some applications are focused on sub-micron particle removal, others demand robust throughput at economical price points.

Customized to meet virtually any footprint and Photo Mask Size Toho Technology Photo Mask Cleaning systems Applications include;

Clean Room Compatible

• Color Filter Process: Lithographic Mask Cleaning

• Cell Process: Photo-alignment Mask Cleaning

• Touch Panel Process: Lithographic Mask Cleaning

Long Term Value

Toho Technology Wet Process Solutions offer outstanding value with additional benefits that make Toho the clear best choice for long term value and performance. High-performance cleaning equipment with Toho process technology ensures best cleaning results. Process Engineers who select Toho Equipment enjoy product enhancements and benefits such as;

Outstanding Customer Support

• Maintenance & Operations Training at Source & Site acceptance

• Training for all Preventative Maintenance & Repair techniques

• Bilingual Assistance as needed

• Trained Service Technicians on-site during and after installations

• Local US Service Technician Presence

• Optional Remote Access software for troubleshooting and programming assistance

• PLC programming support

• Global Compliance

- NFPA codes and regulations, NEC, OSHA

- CE Compliance as needed

- SEMI S2-93A

Engineered for Quality & Performance

• Designed with Japanese Quality Standards and attention to detail and workmanship

• Low Cost of Ownership with best in class material grades

• User Friendly Software Interface customized to unique applications

• Reduced Environmental impact with noise suppression, filtration systems and re-circulation systems

• N2 Purge to Prevent bacteria build up

• ESD Suppression with Ionizer bars at Un-Load

• Automatic Chamber cleaning

• Automatic line purge

Flexible Modular Configurations

• Engineered for throughput, facility requirements

• Full Pre-Assembly Spec Review for customer Engineering and Material changes

• Lower Throughput Applications

• Limited footprint requirements

• Manual Load / Unload

• Bacteria Prevention systems to stop water born contaminants

Modular Design

Toho Technology Wet Process Solutions meet stringent specifications designed for the semiconductor industry but allow for modular customization to fit all applications. While each machine is engineered at the component level to meet individual customer requirements, Toho systems offer outstanding reliability and flexible process control. User Programmable features ensure consistent processing and monitoring while a wide variety of adjustable parameters allow for optimum utilization of Fab assets.

Full Range Spec Capabilities

• Compatible with Mask Sizes up to 1600mm x 1800mm x 17mm

• 60 Minute TACT time

Cleaning Efficiencies

• High Performance Mask Cleaning

• Detach, Removes particles via Multiple Dynamic Cleaning Processes

Process Monitor Control

• Recipe Control Settings

• Direction, Speed, Pressure of Brush and Wet modules

• Surfactant Mix, Dispense and Recycle

• Water Pressure

• Data logging, Error Logging

• Resistivity, Ph

• Water Temperature

Options and Accessories

3D Analysis Software Upgrade

Callibration Mirror Standards

Wafer Stress Pair Calibration Standards

Gas Panel

Vibration Table / Accessories

Extended Warranty

Auto-Rotation

Low-Temperature Module

Odd-size Rings and Adapters

Want More Information?

Andy Slater

Head of Sales

With over 20 years of experience with Toho Technology, Andy is your go-to person for all product questions.

Phil Slater

Service Manager

Need to troubleshoot or schedule a service call? Phil and the Toho technicians are ready to help.